6×8 plans for building a storage shed

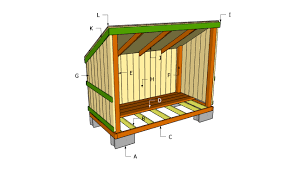

A 6 x 8 storage shed is a very popular size for many homeowners. The dimensions of the building are 6 ft by 8 ft which is a nice size for storing larger tools, lumber, and other items. These are the best used for 6×8 shed plans.

There are also many options in terms of choosing materials for your new shed such as wood or metal. A great advantage to this size of the shed is that you can move it if needed and it will be easier to store if you ever need to find space for it.

Is a six by eight shed the right size?

A 6×8 storage shed is a great option for small-space living. It is usually small enough to fit in one corner of the backyard and can be used for tools, gardening supplies, or even as a temporary garage. The dimensions are 6 ft by 8 ft.

One of the most popular garden sheds on the market today is the 6×8 storage shed. This size often fits in one corner of the yard and has adequate space inside to store anything from gardening supplies to tools or maybe even a temporary garage if needed.

The dimensions are 6 ft wide by 8 ft deep which gives you a total square footage of 56 sqft when it’s all said and done.

The 6×8 wood shed

A 6×8 wood shed is a great way to store your outdoor belongings. It can be used to store anything from lawn equipment, gardening tools, patio furniture, or even an ATV.

The average cost of a 6×8 wood shed is around $1,500-2,000. One option for purchasing such a shed is to buy directly from the manufacturer and have it delivered on-site. This will run about $1,000-$2,000 depending on the size and location of the delivery.

Are Free 6×8 Plans the right choice?

Another option for purchasing a 6×8 wood shed is to purchase one that has already been assembled and installed at a local home improvement store like Lowe’s or Home Depot for $1,500-$4,000 depending on the size of both the shipping container and thickness of sheeting material used in construction.

Another option available at these retailers are pre-built sheds that are built with thicker materials but come with less features than those constructed by manufacturers; these cost between $500-$800 depending on size.

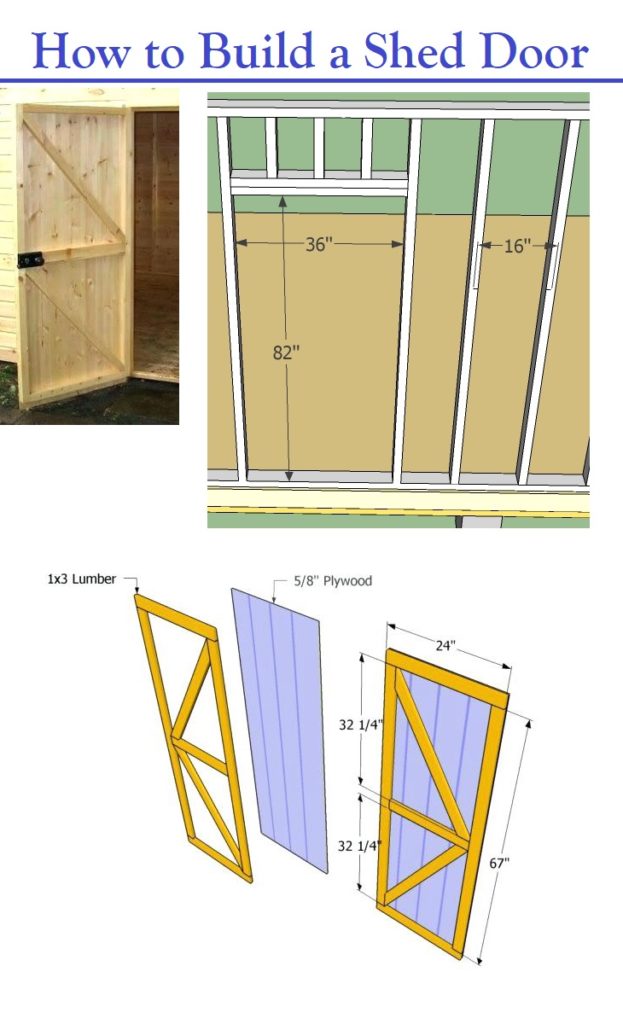

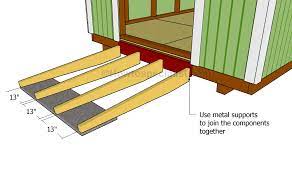

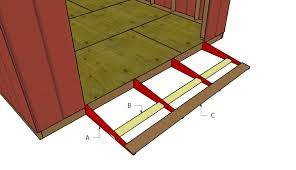

Chose shed plans with, blueprints, door, roof, and floor

6×8 shed building plans, woodworking plans. A 6×8 shed kit is a great way to get the perfect size for your needs. You can use it as a storage space for anything from gardening tools to lawnmowers.

A 6×8 shed kit is a large enough size that you will not have any trouble finding enough room for all of your belongings.

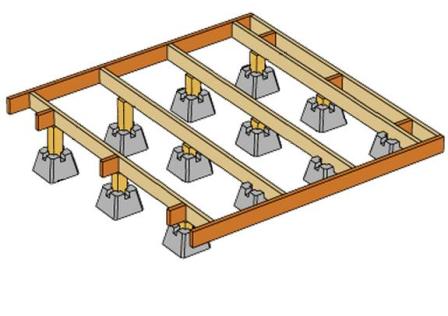

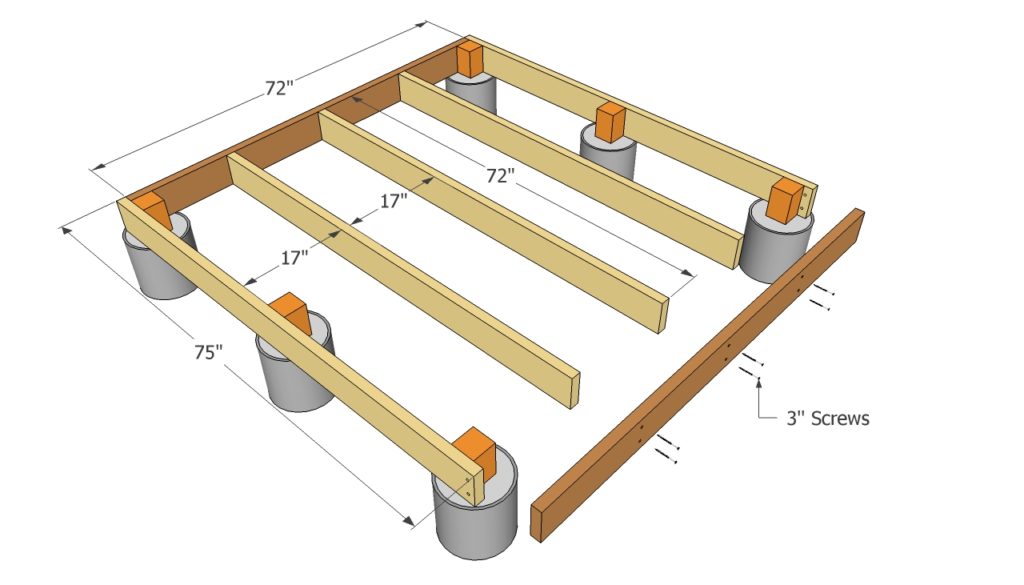

A concrete foundation is a good option for a small shed

6×8 lean to shed are built for storage and working on projects. They are usually framed with 2×4’s and covered in metal roofing or metal roofing.

A 6×8 lean-to shed is built with a set of posts at the front, back, and corners of the building. These posts also serve as framing for the door opening in the front wall.

Once these posts are framed in, they can be filled with 2×4 studs or sheet goods perpendicular to the post frame (or plumb). The wall height should be 4′-9″ high with a sloping pitch towards the rear of 5:12 (1/2 inch rise per foot) A 6×8 lean to shed can have windows and doors installed as needed. Windows should be 3 feet from ground level for easy access.

A 6×8 lean-to shed is a small and simple shed that is built with a roof, but no walls. It has enough space for some tools and a car but is more often built to be used as an outdoor workspace.

The construction of the lean-to shed is not complicated and it can be done by someone who has experience with cutting wood.

The way this type of lean-to-shed works is that one side of the roof rests on the ground while the other side leans against the wall of another structure like a house or garage.

This provides shelter from sun, rain, wind, and snow for whoever might be working at one end of this type of building. They are usually about six feet wide by eight feet long so they can easily fit in tight spaces such as an alleyway or open corner near your house or garage

Maybe your plans could be used to build a chicken coop

6×8 chicken coop is a space-saving, easy-to-build enclosure that provides shelter and protection while keeping your chickens safe from predators.

The 6×8 chicken coop can be built with a variety of materials, such as lumber, metal sheeting or PVC pipe, and plastic sheeting. The design consists of two 3-foot by 9-foot panels attached together side by side on their long sides with generous overlap at the corners.

A 6×8 chicken coop is also a very manageable size for most people with a small acreage. The plan layout is similar to that of a larger coop, but it’s scaled down to fit the smaller space.

You can have up to 4 nest boxes or 2 roosting perches in the 6×8 chicken coop. Most people would use the roosting perches as nests because this would then allow them more nesting boxes for their chickens.

Your shed plans could include shelves that can mount to the walls

The main difference between this and other sizes is that you’ll need shelving units to store feed and water on each side of the 8-foot-long wall, instead of along one side like in the 10×12 design.

This will help make sure you have enough room for your chickens to move around comfortably while they are inside the coop, and will cut down on some feed wastage as well!

With a shed kit, you wouldn’t need free 6×8 shed plans

6×8 wood shed kit – Sheds for sale Sheds are essential to any household because of their practical and economical qualities. If you’re one of the people that have been looking for sheds for sale, then it’s time to stop your search.

These sheds come in many shapes and sizes, which is perfect if you’re planning on adding a new shed to your property. One of the many things that make these sheds great is they can be installed with ease. This means if you don’t have a lot of skills or experience in carpentry, this will not hinder your ability to build a shed.

6×8 storage buildings, 6×8 Storage Buildings A 6×8 storage building is perfect for storing garden equipment, tools, and other items that you don’t need to use on a daily basis.

The size of this shed is good for people with limited space in their backyard. You can use the rectangular shape to your advantage and create a windowless room by installing a door at each end of the building.